Information technologies in construction: significance for the industry

The modern construction industry already operates with more than a dozen technologies that are most in demand in construction. Our review covers the most progressive and popular IT technologies and innovative materials in construction, which are increasingly integrated into the construction industry every year, realizing the most daring ideas of the future.

Industry Features

The construction industry is often criticized for excessive conservatism, standardization and red tape in the workflow. However, it is not easy to introduce the latest technologies in construction, since the main requirements for objects are safety, i.e. each technology must have a regulatory framework, standardization and self-sufficiency: the final cost for its development must be adequate, and the efficiency in reducing costs in the future must be significant , plus, prolonged in time. Any technology requires appropriate design and a whole range of work of the project team, quality control, as well as staff training.

The main advantages of technology

But the growth of cities and population, as well as a new format for the level of human communications in the era of BIG DATA, the growth of economies and the well-being of people, has activated the construction industry for a more dynamic integration of innovations and technological solutions. Therefore, new technologies in construction in the world are actively promoted and used.

In addition, the very speed of technology development leads to a large-scale digitization of the construction industry. And the question of applying IT technologies is already a question of competitiveness. Construction innovations transform the construction site and increase profits, as well as win project tenders.

Since it is innovations that bring economic benefits and increase the competitiveness of a particular construction company, and ultimately realize the client's request with maximum efficiency.

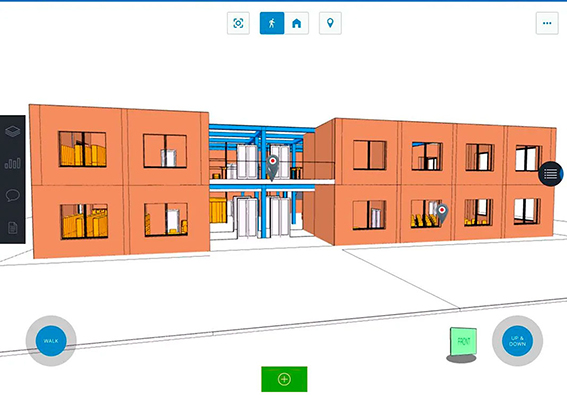

1. BIM

BIM - (from the English building information modeling) is almost the main "whale" in modern design and the main technology that will become mandatory in Russia from 2021 for the construction of budget facilities, and from 2023 - everywhere in the country. The technology implies not just a virtual modeling of a building, it is a complex digital representation of the physical and functional characteristics of an object. BIM takes into account not just the construction, but also the equipment, management, operation of the facility, the prospect of repair or demolition, that is, covering the entire life cycle of the facility as a whole. All components and nuances in the design that are related to the object,BIM - (from the English building information modeling) is almost the main "whale" in modern design and the main technology that will become mandatory in Russia from 2021 for the construction of budget facilities, and from 2023 - everywhere in the country. The technology implies not just a virtual modeling of a building, it is a complex digital representation of the physical and functional characteristics of an object. BIM takes into account not just the construction, but also the equipment, management, operation of the facility, the prospect of repair or demolition, that is, covering the entire life cycle of the facility as a whole. All components and nuances in the design that are related to the object are necessarily taken into account and considered in a single project. When removing or replacing any element or addition, the entire model is recalculated with this adjustment.

Thanks to BIM, the created virtual object model allows specialists to:

- see all the problems and inconsistencies;

- approve the expected benefits of the facility;

- possibility to use the model for all project participants;

- make adjustments;

- calculate the estimate;

- control the work process;

- anticipate the risks of a future design;

- calculate resources.

BIM technologies reduce:

- material costs;

- mistakes in projects;

- deadlines.

Having in the arsenal of digital data about the object, the work takes place with the help of a mobile device, thanks to which proper control is carried out at all stages, for example, using the PlanRadar functionality. This solution greatly simplifies the management and control of construction processes, optimizes the result.

Unfortunately, according to the Russian Ministry of Construction, only 5-7% of companies use BIM (mainly in metropolitan areas and large companies), other new technologies in construction in Russia are even less common.

2. ECO-FRIENDLY BUILDINGS

The topic of "sustainable development" has been discussed in society for more than a year, and the construction industry is also trying on this trend. The minimum impact of buildings on the environment, both during the construction process and throughout the entire life cycle, comes to the fore.

Such buildings use water and electricity efficiently, and carbon dioxide emissions from them are minimal. They do not pose a threat to natural resources even after decommissioning. And another important quality of a “sustainable” architecture is user comfort. Moreover, "green" solutions are evolving:

- Instead of solar panels - a transparent film based on organic photovoltaic cells.

- Tanks for collecting rainwater.

- "Green" roofs as thermo-acoustic protection.

- Vertical gardens for indoor temperature control.

- Light domes to maximize the use of natural light.

- Eco-friendly brick.

- Waste materials are given a second life: floor coverings, old furniture, wood are reused.

On the one hand, this trend allows construction companies and investors to reduce costs, on the other hand, it is a way to stand out from the competition thanks to principles that are increasingly valued in society.

3. 3D PRINT

With the help of 3D printing, you can make both individual structural elements and entire houses. For example, the manufacture of a house with an area of 55-75 square meters. m takes only a day. People do not participate in the construction process itself - everything is done by a machine according to a given project, which is controlled by the operator. Waste from manufacturing is almost zero, since the 3D printer consumes exactly as many materials as required.

Various methods are already being used:

- The robotic arm moves along the rail and applies the concrete layer by layer. The principle is the same as that of desktop 3D printers, which use layer-by-layer deposition of molten polymer according to a predetermined algorithm.

- Sand 3D printing has more in common with industrial technologies. It was first tested by the Italian architect Enrico Dini, who built his D-Shape 3D printer. The machine distributes a layer of sand powder, then strengthens the shape of the structure with a binder.

- For metal structures that must withstand heavy loads, 3D printing can be applied using an industrial robot with the function of a welding machine. Thus, the technology of the Dutch company MX3D allows you to print metal structures in 3D along 6 axes.

4. Robotization and exoskeletons

Despite the obvious use of the maximum replacement of human labor in such an area as construction, manual labor still prevails and is sometimes the only productivity option. Unfortunately, the construction site is too mobile and rapidly changing environment, where there is no place for robots without fantastic AI, because they act according to a given algorithm. But gradually, construction is introducing smart solutions, in particular, the use of drones. And this technology has much more to do with real estate and commercial purposes than just aerial photography of objects.

Drones are useful as:

- security control: site monitoring with cameras and detection of hazardous areas. There is no need to personally check the construction site, but immediately send people to solve the problem;

- drones supplying materials to the facility, reducing the number of vehicles;

- drones-masons. Increased speed and quality of routine work

- drones for demolition of building elements at the end of the project. Although this is slower, it is undoubtedly a cheaper and safer solution;

- security drones. Thefts in construction, alas, are ubiquitous, so robots can be used to reduce the cost of this article.

Exoskeletons

Robotic exoskeletons will speed up work and productivity on the construction site, as the power of a person in such a "suit" increases many times over, while the work is much safer.

The German biomechanical company Ottobock and the Swedish Hilti have developed the EXO-O1 exoskeleton for builders, which entered the market as early as 2020.

EXO-O1, Hilti is a passive type exoskeleton - that is, it does not require a power source. It is a design worn on the upper body, which reduces the weight of the arms due to the load on the hips. Therefore, it is suitable for work performed above shoulder level. The weight from the arms is transferred to the hips through the forearm supports using mechanical cable tension. Testing has shown that the load on the muscles is reduced by up to 47%. This means increased worker productivity, as fatigue reduces. Behind such structures is the future of modern construction.

CONCLUSION

According to McKinsey & Company, the construction industry is inherently slow to adopt new technologies, driven by cyclical demand for construction services, high price competition, and high risks that limit capital investment in innovation. However, the coronavirus outbreak has pushed absolutely all industries to implement digital and other technologies that they used to be skeptical about.

How relevant the above trends will be for the Russian construction market, time will tell. One thing is clear: those who innovate first have a distinct advantage.

Links to the source — https://www.sgs.ru/ru-ru/news/2021/02/9-innovacionnyh-trendov-v-stroitelstve